【CERTIFICATE OF ANALYSIS】

Product Information | |

Product Name

| Strawberry Lemongrass Flavor Black Tea for bubble tea |

Net WT.

| 600g 24 bags / carton |

Taste Description

| Bitterness:1 Astringency:3 Aftertaste:2 Freshness:2 Water:2 |

Shelf Life

| 2 years(Sealed).Store in a cool dry place out of direct sunlight. Keep the package tightly closed. |

Origin

| India |

Suggested Practice | Unsweetened iced tea/Iced tea/Sparkling drink/Milk tea |

About Us

Tachungho International Co., Ltd. was founded in 2019, specializing in the production and manufacturing of tea leaves and drink powder, with sales channels covering the six continents worldwide. At present, the company operation insists on the four main principles of “On-Time Delivery, Stable Quality, Environmental Hygiene and One-Stop Service.”

With the continuously rising global drink market and the constantly increasing demand, we have invested in an “automated production line,” integrating the factory with “AIOT smart digitization,” thereby having control over every loop of operations to reduce the cost, control the quality and enhance the efficacy. It is constructed conforming to the FSSC 22000 food safety system and the MUI Halal Certification Standards, with the setup of high-spec “Class 100,000 Cleanroom QA Laboratory” to stringently control the quality, to build the safest and the most stable protective shield. The dedicated R&D department observes the market trend of drinks, as well as collects the latest raw materials from around the world to create new ideal exclusive products for our clients, thereby enhancing competitiveness and completing market segmentation.

▲Please come to Tachungho if you need massive production for tea leaves and drink powder!!!

▲Please come to Tachungho if you have ideas regarding customized tea leaves and drink powder!!!

▲Please come to Tachungho if you urgently need a collaborative company with stable product quality!!!

The stringent “Production Process” from incoming materials management to production and quality inspection tests

| Floor | Operations | Description |

|---|---|---|

Floor 2 | R&D Center | Professional R&D facilities and team to develop market trends, customize personalized products |

Floor 1 | Raw Materials Warehousing | The warehouse confirms the items and quantity of the raw materials, as well as sampling for inspection |

Floor 2 | Incoming Quality Control | QC personnel conduct sampling tests on every batch of raw materials |

Floor 4 | Raw Materials Storage | Store into the warehouse according to each batch No. and storage criteria |

Floors 4, 5 | Feed Zone | Pour the raw materials into the mixer downstairs, there is a first impurity elimination safety mechanism set up at the feed opening |

| Floor 4 | Mix Raw Materials | Each zone is an independent operating zone to avoid cross-contamination, there is also a high-spec metal screening machine to allow the mixing process in conformance with the safety regulations |

| Floor 3 | Packaging Production Line | The packaging machines in the entire zone adopted automated processing, effectively enhancing the production capacity |

| Floor 2 | Product Inspection | QA personnel conduct sampling tests on every batch of products |

| Floor 1 | Product Warehousing | Utilizes AIOT Digiwin Smart Logistics System to have 100% control over the incoming and outgoing stocks of the raw materials and products |

Tachungho Smart Factory

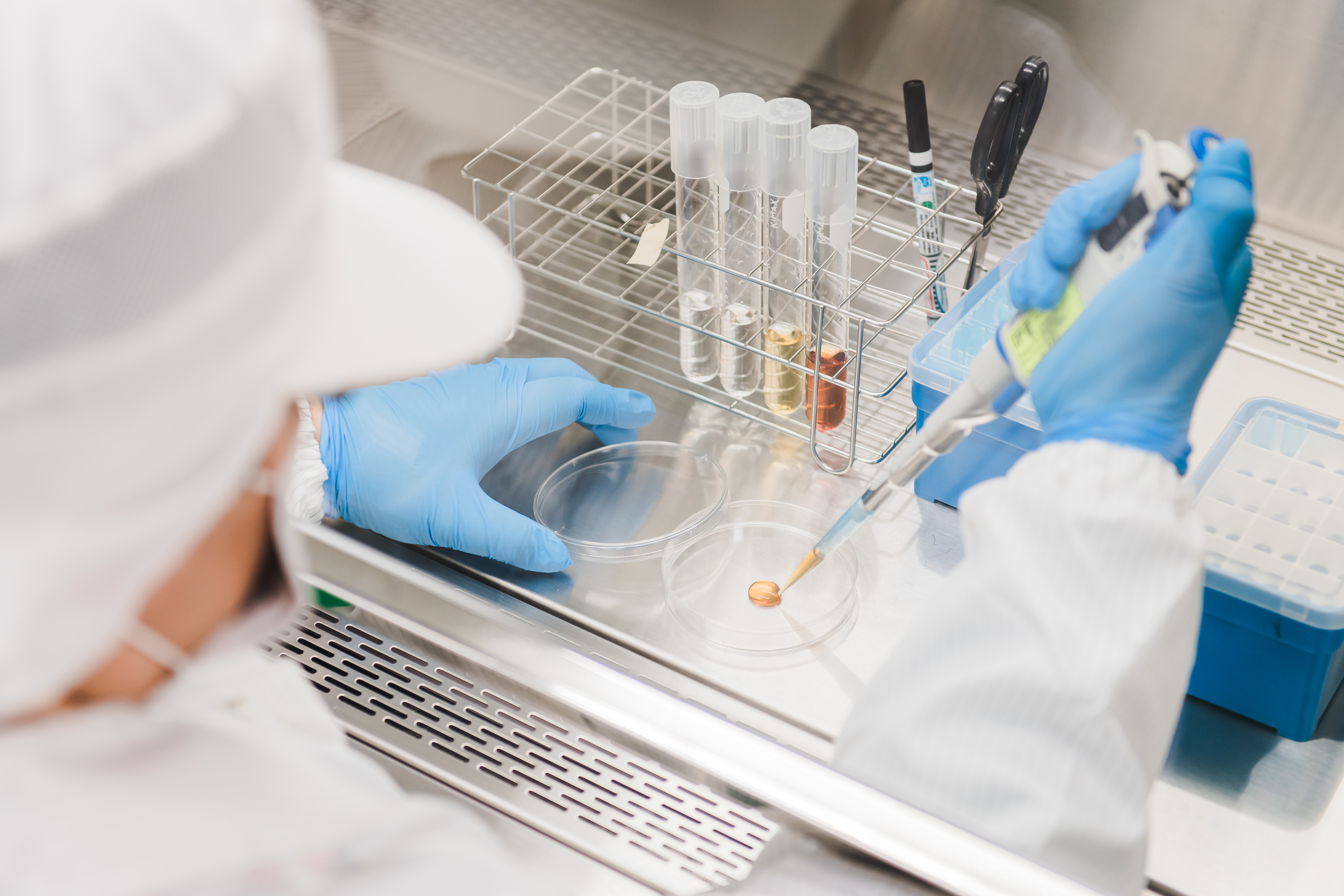

Stringently carries out “microorganism experiment” and “physical property experiment” to offer 100% quality guarantee

▲Tea leaves must go through tests including “water content,” “brewing test,” “form of tea leaf,” “Escherichia coli” and “pesticide residue.”

▲Powders must go through tests including “water content,” “looks and taste evaluation,” “Escherichia coli (group)” and “plate count.”

The clean and tidy production environment makes it a food factory conforming to international regulations.

▲The indoor temperature and humidity are constantly controlled at 37℃ room temperature and less than 55 degrees of humidity according to the food safety class.

▲A hand-washing and sterilizing zone and dust room are set up at the entrance.

▲Purchased metal detection machine imported from Germany and powder line automatic safety device to manufacture products without concerns.

▲We have passed certifications including FSSC22000, HACCP, ISO9001, ISO22000 and MUI HALAL, demonstrating the enterprise's credibility and product safety.

We listen to your needs, be your most reliable backup

▲We have abundant drink market development experience, fully understand the operating demands of the industry and the products developed will all be physically operated to ensure the best user experience for the end customers.

▲In response to market segmentation, we are equipped with comprehensive tea-making and powder-making facilities, such as a tea-roasting room, commercialized tea-bag machine…etc.

▲Considering tea flavors, stable quality, market demands and manufacturing cost…etc., we have collected tea leaf raw materials from tea production regions worldwide to proceed with the blending to produce exclusive tea leaf products.

▲We stringently select raw materials, fragrances and colorings and further consider the fluidity, color and flavor to dissolving speed of the content in order to develop a characteristic and more convenient drink powder.

Content of Services

▲Tea leaf manufacturing and wholesaling

▲Customized tea leaf blending

▲Drink powder manufacturing and wholesaling

▲Customized drink powder R&D

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.